Yard Control Tower

Reduce waiting times and increase volume

It is quite a challenge to maintain an overview of the site and the capacity that is in use. What has become self-evident for the warehouse is still lacking for the industrial site itself: the ability to optimize and automate processes.

For high-volume sites, every minute is critical. Despite a good capacity planning, the real-time processes are influenced by external factors such as traffic, production delays, driving and rest times.

Automated communication in the appropriate language for the driver saves time and capacity, the use of dock sensors ensures real-time visibility of the use of loading docks and, by integrating IP video, any damage claims can easily be verified, often resulting in savings in addition to the reduction of waiting costs.

The Peripass platform offers new insights as a basis for handling more volume, enabling faster throughput and avoiding errors during loading and unloading. All data on arrival and departure times, turnaround times or compliance with rules represents an opportunity to analyze the performance of carriers.

Tracking of carrier commitments

Because all times (arrival, dispatch, departure, etc.) are logged, it becomes much easier to follow up the agreements & SLAs made with carriers, thanks to the logistics dashboard.

Reduce idle dock labor

By automatically transmitting tasks according to a specific priority, you avoid warehouse workers having to wait for new instructions and unnecessary downtime.

Reduce detention & demurrage expenses by 85%

On an average site, we are able to reduce waiting costs charged by carriers by 85%.

Why choose us

Benefit from our innovative Yard Management features

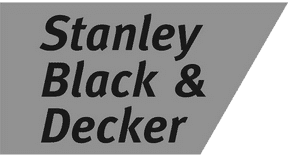

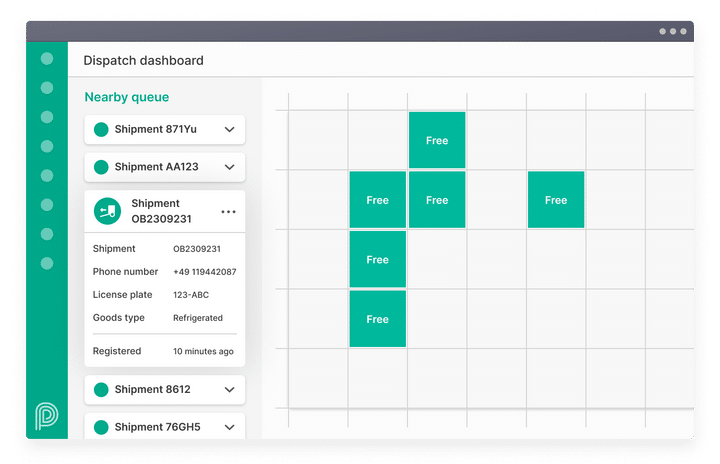

Digital twin & dispatch dashboard

Centralize all logistics information in one place and monitor your whole logistics site at a glance.

See all logistics information in one handy dashboard tailored specifically to your site. Combine information on scheduled shipments and slot booking systems with the current situation at the loading locations and at parking sites.

Access Control System integration

Digitalize reception of drivers, visitors and contractors and make communication and access to the site as fast as it can be.

Keep a real-time view of all the persons who have arrived and departed from your site. Prevent unauthorized access with personal access codes or badges. This also ensures that Peripass knows with 100% certainty who is in which zones on the site and how long they were there. Peripass listens to the access control systems, tracks all data and gives you all the information instantly and correctly.

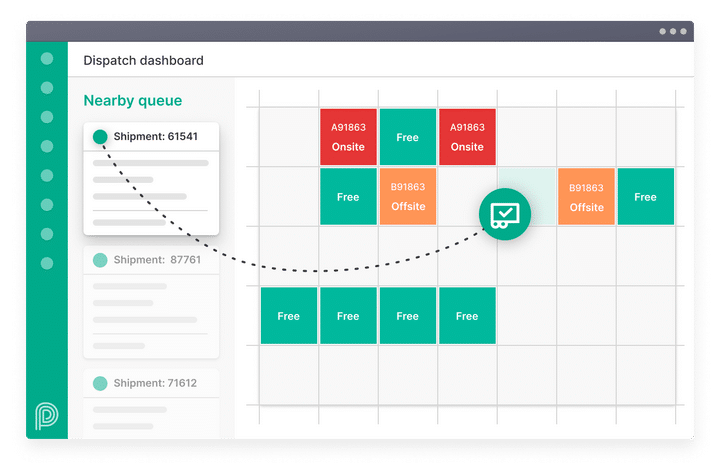

Queue Capacity Management

Manage queue capacity at peak moments or for locations with limited space or backup-prone sites.

Define your own priorities for calling up drivers to the nearest parking: FIFO, LAFO or based on time scheduled in your WMS, TMS or ERP system.

Customer stories

Our customers’ success stories

We would rather let our customers speak for themselves. Read our customer stories and learn from the experiences of various logistics, distribution and production companies. They explain how they use the Peripass platform to reduce costs, improve efficiency and make the site safer. Discover their smart flows …

“We can now work much more objectively, with a data-driven approach and on the basis of KPIs. That is in keeping with our international objectives.”

Logistics & Distribution – Belgium, Puurs

The logistics knowledge of Peripass’s implementation consultants, combined with their wealth of experience acquired on other projects, was maximally deployed to devise solutions for the optimization of processes for ID Logistics.

Logistics & Distribution – The Netherlands, ‘s Hertogenbosch