Peripass optimizes logistics sites at the same time as meeting the increasing demand for contactless reception.

Aside from its impact on health, Covid-19 is having a significant and lasting impact on the Belgian and international economy. That is why companies are looking for structural solutions. But that’s not self-evident when rules are constantly changing. Peripass is launching new features for mapping out companies’ logistics processes in order to further optimize them. At the same time, Peripass also fits the current trend towards contact-free reception. The result? Greater efficiency and transparency throughout the entire site.

In order to prevent the further spread of the virus as much as possible, many companies have taken various measures, such as installing plexiglas screens or providing face masks and sanitizer gel. “However, we notice an increasing demand from the market for sustainable, long-term solutions with a focus on respecting social distancing, such as the contact-free registration of drivers,” explains Caroline Vanderbauwede, Marketing Manager of Peripass. “Peripass enables processes to be identified, and thanks to the logistical expertise we have acquired in various sectors, to be digitized and optimized. Where Peripass is already in use, companies benefit from a lasting positive impact in several areas: more visibility, increased security and improved efficiency. And with savings as a result.”

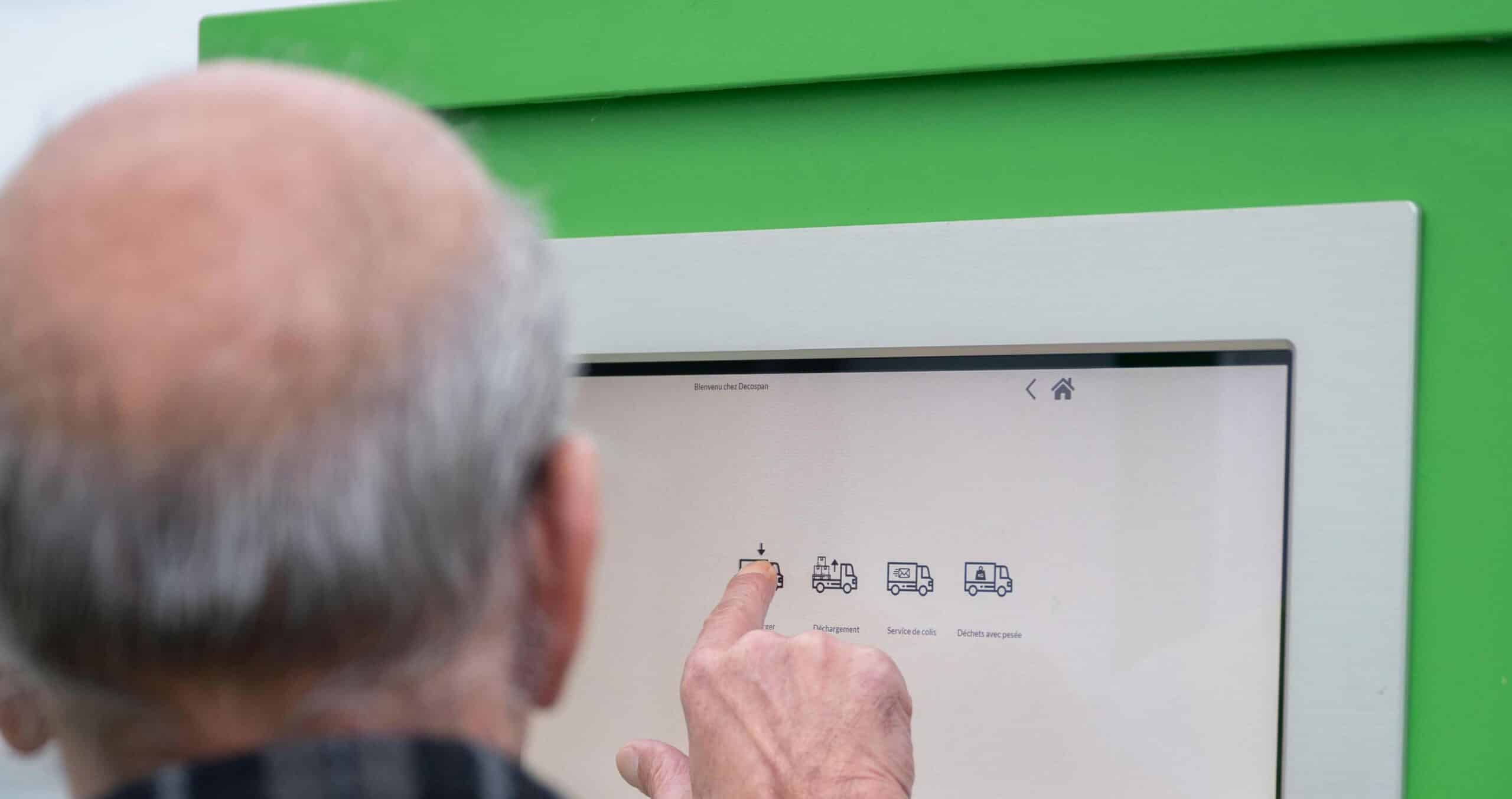

Digitizing the registration process – via Self Service Access – saves on manual work, you get a much better overview of who is on the site and the registration process is faster. Fewer trucks waiting in line means higher volume on the site. The process meets the demands of many logistic sites: avoiding physical contact between staff and drivers. “Many companies receive international drivers and because of the language barrier, this is not always that easy,” explains Caroline Vanderbauwede. “Thanks to the multilingual and automated communication of the platform, all instructions are passed on in the mother tongue of the driver.”

Peripass combines all benefits of integrated logistics processes: from real-time visibility to the automation and digitization of tasks. The insight into site operations provided by Yard Control Tower enables processes to be optimized, shortening lead times, increasing volume and reducing waiting costs by 85%. The automation of the logistics processes allows personnel costs to be reduced. Yard Automation also results in increased safety and security. By using Yard Asset Management, you can manage all assets on site with full peace of mind: no risk of lost trailers or containers or incorrect transports leaving the site. Yard Task Management centralizes and digitizes the operations of shunters, forklift truck drivers and security on the site.

Latest blog posts

Real-time insights with live dashboards

Product updateBring your Peripass data to life with dashboards Peripass yard management software provides dispatchers with a clear idea of the activities on the yard of their production site or warehouse. All truck drivers are registered, each truck is tracked &...

Peripass Secures €7.5 Million to Digitize the Logistics Sector Globally

Peripass Secures €7.5 Million to Digitize the Logistics Sector Globally Belgium, February 1, 2024 - Peripass, the leading SaaS scale-up revolutionising logistics sites by digitally organising truck movements, has successfully secured funding to accelerate its global...

ZF Innovating their site in Bouzonville with Yard Management

We are thrilled to announce our collaboration with ZF, a global technology leader in automotive and industrial innovation. This partnership, aligned with Peripass's mission to streamline logistics, not only welcomes ZF as our newest collaborator but also addresses...