“Now the entire process is much safer, much better organized and more seamless.”

Belgium, Wevelgem

December 2017

trucks per day

“There was a time, when I looked out of the window and saw the chaos and the safety issues. I wanted a system that would solve this and could run 24/7. That’s how we ended up signing with Peripass. ”

Wim Muylaert, logistics manager, explains why Alpro chose to implement Peripass: “There have been times when I was sick with worry when I looked out of the window and saw the chaos and the safety issues. I wanted a system that would solve this and could run 24/7. That’s how we ended up signing with Peripass.”

Alpro bought a nearby site to be used as a car park for its employees and a car park where trucks could wait. Wim Muylaert: “We now have 32 parking spaces for trucks in our wait zone. Previously some of these trucks would be parked on the street and onsite. This was a chaotic situation, which also caused major safety issues. Drivers would block the passage or fight about who arrived first, even though we determine who has priority.”

“There were often dangerous situations at our gates, with cars and bikes. I often told myself: “One day soon, an accident’s going to happen”. This was the most important factor for in terms of urgency: not the logistical inefficiencies, I just wanted to prevent accidents from happening. Especially a collision of a truck and a cyclist – this is probably the worst thing that could happen. Fortunately we now no longer have to worry about this.”

“We also installed additional safety cameras in the car park to prevent undesirable situations. In the past, drivers decided to organize a barbecue onsite. While I understand that this can be nice when you’ve driven a long distance, it’s not really safe if you know what I mean.” (laughs).

“More languages, less problems”

“In the past all the drivers would come to our office individually to check in. Nowadays we have drivers from all over Europe, from all over the place, which complicated communication. Face-to-face contact was also quite difficult, because you have drivers who are calm and others who are completely incapable of remaining calm. Thanks to Peripass, life has become much easier. The drivers now check in at one of the self-service kiosks in one of the 26 languages in which Peripass is available. They use the PO number that Alpro generated for them to do this. They also are informed about onsite health and safety rules. We also ask them how many hours of rest they still have to take, so we can factor this in during the dispatching process. We also check whether the truck has empty pallets on board. If that is the case, the truck is automatically diverted to another route, and the pallets are offloaded.”

“Now the entire process is much safer, much better organized and more seamless.”

“Peripass sets an example for many other applications and is extremely relevant for companies with a lot of throughput.”

Like in a film

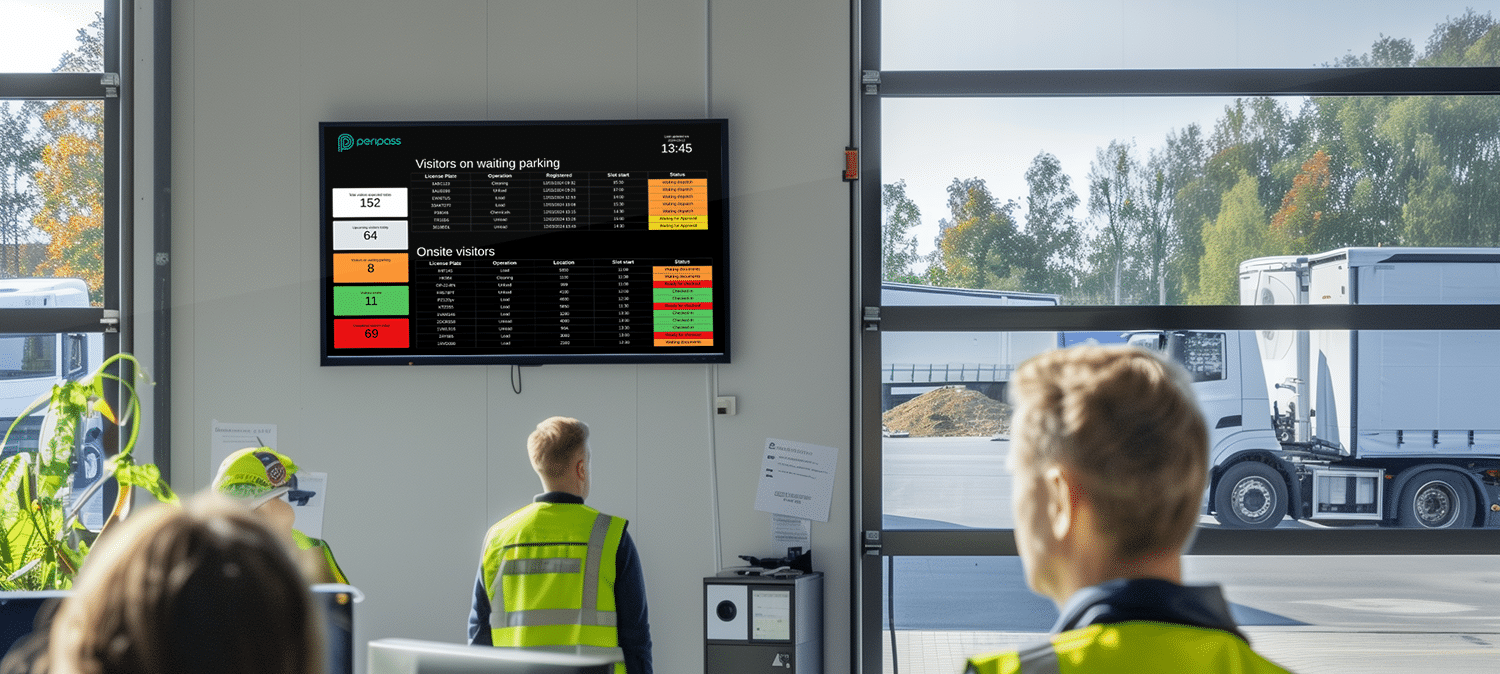

Every day, we process 120 trucks on average. Some are too early, some too late, which means we constantly have to adapt our planning schedules. We use the Peripass platform to process the right truck, sending a text message to the driver. This is very easy. It’s a lot like the film. We drag a truck to one of the 25 gates on our screen. The driver is then automatically notified that we are ready to receive him. He is informed which route he must follow on our site, and at which gate he is expected. In addition to the check-in process, we can also notify drivers if our production is running behind. This allows them to stop and rest or do some shopping nearby. This has solved all the problems we had, in terms of chaos, people who wanted to jump the queue or purposefully blocked each other.”

Drivers who are on time are rewarded

“Where possible, we always try to give priority to trucks that are on time. We have a transport planning department, which draws up an hour planning schedule for all the trucks. This planning schedule is automatically forwarded to the road haulier. This informs them that they have to plan a driver who has to collect a shipment at a specific time. If we say that the driver should arrive at 10 am and he checks in at 10 am, then this gentleman will definitely be given the green light immediately. If the driver is late, then the other trucks that are on time or too early will still be given priority. This is our way of rewarding trucks that are on time. Otherwise everyone does what he wants. And we can’t work that way.”

“We have two different types of products: drinks that are transported at room temperature and yoghurt and ice-cream which must be chilled at all times. We may not load a truck if it doesn’t have the right temperature. The Peripass dispatching screen indicates when a chilled transport arrives, so we can process it as soon as possible.”

30 minutes gained for every shipment

“In our old system, the transport planning schedule indicated which pallets had to be picked in the warehouse. These were prepared near the gate. And then you had to hope that your driver was on time. You had no other choice. Nowadays we run a fully-automated warehouse, a 45-metre tall high-bay warehouse with 35,000 pallets, and fully-automated cranes. Thanks to Peripass we always know which trucks are waiting in the car park. As soon as we notify a driver that he can drive up to the gate, the right pallets are picked in the high-bay warehouse. All our employees have to do is bridge the last metres to the loading dock. By the time the truck docks, the pallets are already there, waiting to be loaded.”

“It’s always nice to see how impressed visitors are with our approach and our system.”

Connection with SAP

“All the information we enter in Peripass is fed into our SAP system, which controls all our other activities, such as our invoicing and business analytics. Peripass connected very easily with our SAP interface. We’ve had some problems in the past with other projects, so we expected the worst (laughs). You can feel that they have a lot of software expertise at Peripass.”

“This is a very time-critical process. Now we succeed in loading a truck every 30 minutes, which is quite fast. We gain 30 minutes per shipment, which is quite fast compared with a classic process.”

“I am very confident that Peripass is a valuable partner, both for us and for other market players.”

State-of-the-art

“Peripass approached us a few years ago with their solution and we knew from the outset that this is what we were looking for. It’s the best system I’ve seen to date on the market. I regularly visit other companies and every time I’m struck by the chaos and how unclear things are. And then I tell myself that we have the best state-of-the-art system in the market. Especially for the type of volumes we process.

We have become a subsidiary of the Danone Group and we regularly receive visitors from around the world. It’s always fun to see how impressed they are with our approach and our system (laughs).

A customer-oriented partner

We’ve worked with them for one year and we have no regrets whatsoever. You can feel how customer-minded they are in everything they do. Peripass is very flexible, the teams thinks along with the customer and is very quick to respond with a solution. They are also very flexible when it comes to answering any additional questions we have. Most other suppliers will respond: “Yes, but that’s not part of the actual project, we need to review everything”, which slows down the process. I also appreciate the fact that they listen to our feedback and include these improvements in new releases.”

Any tips for your colleagues?

“We learnt very quickly that it is really important to send the driver a welcome text message. This informs him that his data and check-in have been processed. In the early days, drivers would still come to the office to check that we knew that they had arrived.”

“I recommend everyone to take a multidisciplinary approach to their project. Make sure that your team members can set aside enough time for the project. Our team was composed of the people who would use the system every day: the logistics manager, the logistics officer, the team leaders and the warehouse managers. The IT team and people in the engineering department provided support for the construction of the new car park and the new access control systems, the barriers, the terminals, and so on.”