CUSTOMER CASE

Peripass at Bridgestone

“By choosing a configurable platform, you can rely on existing features that are already built into the platform.”

– Robbie Gaudesaboos, System and Process Coordinator at Bridgestone Zeebrugge

Belgium, Zeebrugge

February 2022

trucks per day

In 2021, Peripass was implemented at the Zeebrugge site (Belgium). The site faces numerous logistical challenges: the combination of port-related container transport with external transport, a fast lane for fixed carriers, the need for real-time container management and the associated waiting and rental costs. Bridgestone was already working with a Yard Asset Management application, but needed additional fine-tuning and features. They went looking for an off-the-shelf standard package such as Peripass. In other words, not a customized solution. Robbie Gaudesaboos, Systems and Process Coordinator at Bridgestone, was involved in this project and is happy to talk about what Peripass means for Bridgestone.

A Success Story at Bridgestone’s Zeebrugge

“We are thrilled with the successful implementation of Peripass, a configurable platform that has seamlessly integrated into our operations at Bridgestone’s 90,000 m2 warehouse in Zeebrugge. Choosing a dynamic platform has allowed us to leverage existing features and evolve alongside the expanding possibilities it offers. Despite the initial adjustment period post go-live, where we navigated the complexities of live loading, standby loading, and additional container flows from the port, including the installation of an extra registration kiosk for visitors and subcontractors, the entire process was a well-executed puzzle.

Bridgestone’s unique operational structure, without a central dispatching department, required a solution for easy container and truck dispatching by reception staff and warehouse team leaders. Additionally, gaining deeper insights into port-related activities was crucial to managing waiting costs for containers efficiently. With our existing Yard Asset Management system, tailored for the high volume of daily drop-off and pick-up actions, we stand out due to our collaboration with external transporters and a dedicated port traffic partner. The streamlined process has not only simplified operations on our end but has also optimized efficiency for our container supplier, contributing to our overall satisfaction.”

“By choosing a configurable platform, you can rely on existing features that are already built into the platform. What’s more, you can evolve along with the platform’s possibilities.”

“The driver receives the access code, communication about the destination location for the container and which empty container he should take back.”

Automatic dispatch for port-related logistics

“For the unloading of containers, Bridgestone works with a permanent external partner who has access to the Peripass platform via their own login. Bridgestone takes care of the pre-registrations in Peripass by uploading a list of containers that are expected and when they should be on-site. Currently, Peripass runs as a stand-alone solution – for the time being, no integration has been set up with our ERP system and we do not have an external TMS system. All uploads and pre-registrations are currently done via Excel files or manual input.”

“When a driver picks up a container at the port terminal, he logs in on the tablet in the truck. From there, the automatic Peripass dispatching starts, automatically assigning the target location of the container at Bridgestone. At the same time, a PIN code is automatically generated in the Peripass platform to enter the site. This is sent to the drivers via email (on the tablet). In addition to the access code, the driver also receives information on which location the container needs to be dropped off at and which empty container he needs to take back at that time. When the PIN code is entered, Bridgestone immediately knows that the carrier is on site.”

Container management thanks to real-time information

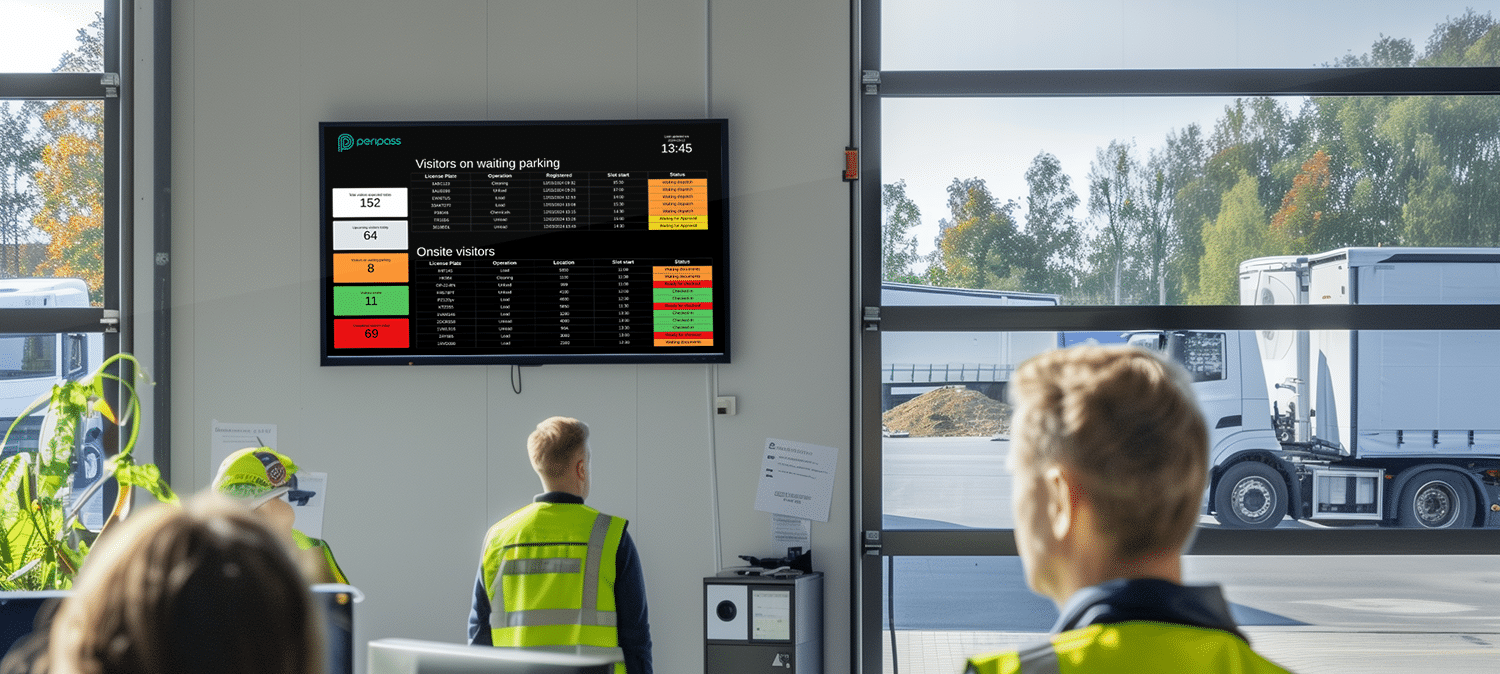

“On the Peripass dispatch dashboard, Bridgestone sees a complete overview of which containers are on the site, at which location, what their status is and how long the container has been here. It also gives you a complete overview of which containers have been picked up. This enables Bridgestone to follow up the agreements with external partners and carriers in detail: have the containers been dropped off at the right locations, at the agreed times? In addition, you can easily check the number of units delivered and collected on a weekly or monthly basis for billing purposes.”

“The great thing about Peripass is that it allows us to prioritize the containers that have been on the site the longest. These are the first to be passed on to be picked up again in order to avoid extra berthing fees. The automatic dispatch is configured in such a way that a driver, who registers, also has to pick up an empty container by default, namely a container that has an ’empty status’.

“The great thing about Peripass is that it allows us to prioritize the containers that have been on the site the longest.”

Pick-up and drop-off with external partners

“The logistics flow with our external partner is made up of pick-ups and drop-offs. There is no live movement included. Because this flow is performed with the same partner as for the container movements, the registration process was also radically simplified here. In a similar way, the registration is done on the tablet in the truck, where the reference number, the container number for drop-off and the name of the driver are requested. The driver can select his name from a drop-down list provided by the external partner, along with the correct email addresses. Automatic triggers are activated on the basis of the data entered, sending the right emails to the right drivers.”

Flexibility in dispatching transports

“The call-up of trucks is done by the reception staff or by our team leaders in the warehouse. In order not to keep our operators in the various warehouses waiting, which take care of loading and unloading, the team leaders also manage the dispatch. This mainly applies to the live loading of non-port related transports. A driver registers at the registration kiosk. A notification email is sent from the platform to the dispatcher. Team leaders do not sit behind their desks, but walk around among the other colleagues in the warehouse. With Peripass, it’s possible to organize the dispatch via a mobile device (iPad).

The team leaders themselves can flexibly handle whether or not trucks are called up, depending on the work. In addition, we work with set triggers: certain transports are designated for a specific part of the warehouse to which an email address is linked. Only the correct team leader of this specific warehouse receives all information via e-mail. After that, the dispatch can be carried out and the driver can be called up very quickly, if the space is available.”

“The team leaders themselves can flexibly handle whether or not trucks are called up, depending on the work.”

Self-Service kiosk for non-port related logistics flows

“At Bridgestone, we also receive trucks that are not related to the port of Zeebrugge on a daily basis. We’ve created a separate logistics flow for them, which requires drivers to first register at the Self-Service kiosk upon arrival. The drivers first choose their preferred language, so that it facilitates all subsequent communication. The driver enters the reference number and his mobile phone number. Peripass sends the PIN code for access to the site together with the correct location to the driver via SMS.

The PIN code is used to drive in and out and to keep track of who is where on the site. The first step is to enter the PIN code at the barrier at the entrance to the site. The moment you drive in, the PIN codes are also activated for another group of access control systems, so that turnstiles can also be used. Drivers use the turnstiles to collect documents at the reception or to use the toilet. As a final step, the PIN code is used to drive back out, after which the PIN code is made invalid.”

“The PIN code is used to drive in and out to keep track of who is where on the site”

Mobile App for planning warehouse workers and Tugmaster drivers

“The Peripass Yard Operator App is used to control the internal movements of Tugmaster drivers: moving units to the quay or from the quay back to the parking lot. We’ve also added additional tasks to this. A series of checks need to be carried out on the basis of predetermined steps. For example, checking the TIR cable (this is the sealing cable for the trailer), checking any external damage, checking the number of planks needed for support during transport of the tires, the cleanliness of the units, etc. We have defined all the different verification steps in a task that can be performed by our team leader in the warehouse or by our Tugmaster driver. Each item can be entered using a drop-down menu.”

“Now all information is immediately linked to the correct units, saving us administrative work.”

“In the past, the verification process was done manually, on paper. Then all the papers were processed and all information was entered into the computer. Now all information is immediately linked to the correct units, saving us administrative work. By working this way, here too, we’re also trying to simplify and standardize all the steps as much as possible.”

“At the same time, by doing the checks before unloading, especially when we notice that a load arrives in very bad condition, we can take pictures of the loads or damage. This allows us to refute claims or directly demonstrate that the damage was not caused at Bridgestone. The photos are also directly linked to the correct unit, so that no additional administration needs to be provided.”

“Photos are directly linked to the correct unit, eliminating the need for additional administration.”

Next steps

“One of the next steps is to install smart cameras at our barriers so that photos can be taken automatically when entering the site. Also, we want to look at the process of Contactless Document Handling in detail and find out the extent to which this could represent added value for us.”