“We can now work much more objectively, with a data-driven approach and on the basis of KPIs.”

trucks processed

FIEGE had a small 20,000 m2 site in Puurs that was recently upgraded to a 50,000 m2 site further to renovation. Christoph Verhavert, Project Manager Belgium at Fiege: “Incoming and outgoing truck traffic used to be very restricted, but now it’s very busy”.

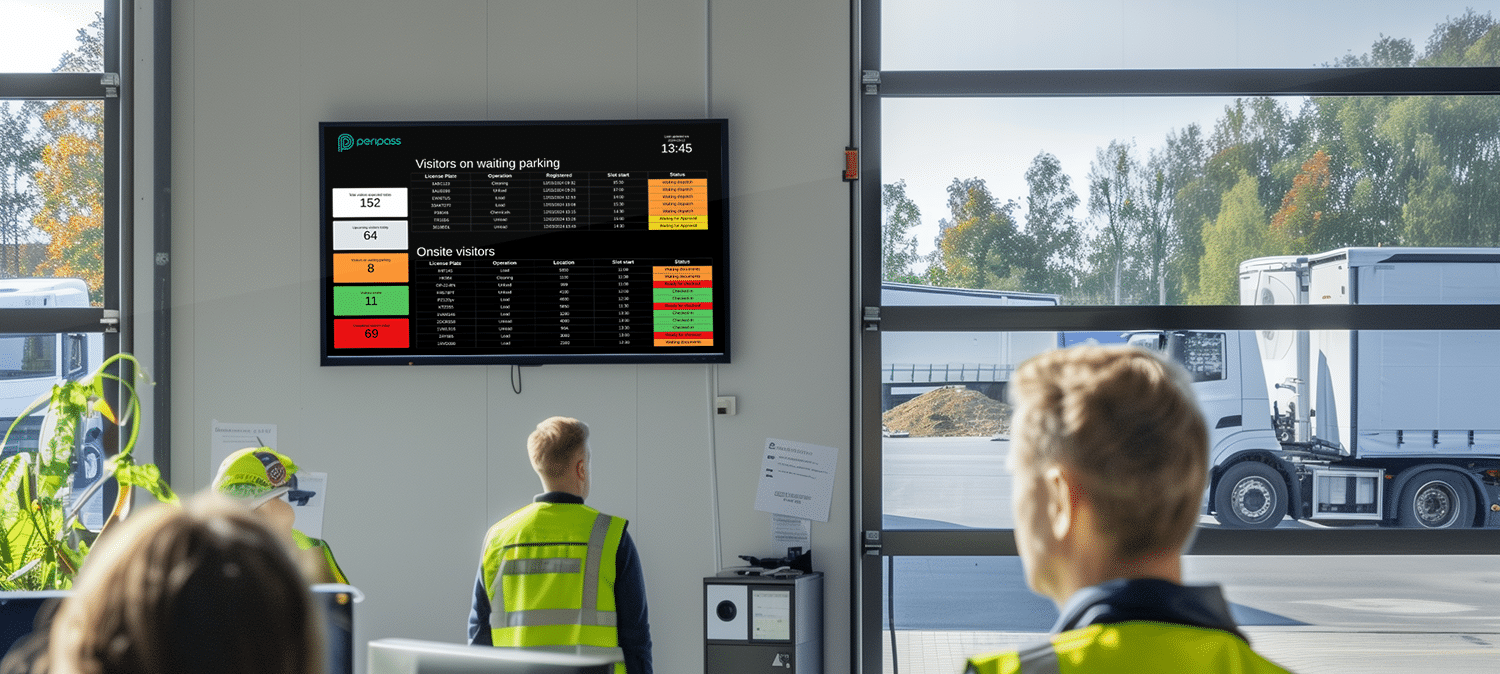

“We have around 80 trucks arriving every day to unload and 40 or so leaving with the outgoing goods, which meant we needed a much better overview. Everyone used to simply drive into the site. Our reception is halfway through the building. The result was that at that spot dangerous manoeuvring was regularly going on – reversing, turning, etc. – with no account being taken of the pedestrians who were winding their way between the trucks at that moment.”

“There was no overall view or coordination, either. Someone who had an appointment at 8 o’clock would drive into the site as early as 6 o’clock and expect to be dealt with, making it very difficult to adhere to a planning with the warehouse. Now that we’ve installed Peripass we only call the trucks in when we can actually load or unload them.”

“Now that we’ve installed Peripass we only call the trucks in when we can actually load or unload them. Incoming and outgoing truck traffic used to be very restricted, but now it’s very busy.”

“It’s true that we’ve waited a long time to get an efficiency process such as this up and running, since it represents a major investment. In addition to the software package, you also have to invest in cameras, fences, barriers, the laying of detection loops under the paving in the parking lot, lighting, signposting, etc. Taken individually these are all minor expenses, but when you add it all up you’re talking about a hefty budget – a budget that has to be approved and freed up. That doesn’t all happen just like that.”

“It was very difficult to adhere to a planning: hauliers would drive whenever it suited them.”

“We combine cross-dock operations with warehousing. We have a large number of very different clients, ranging from the international supermarket chain Makro to e-commerce companies. They all come with their specific processes, which gave us a total of 17 different flows. Our cross-dock services in particular are a challenge. These are often supplied by joint-cargo companies and those drivers were in the habit of turning up here without an appointment. We had absolutely no means of keeping these guys out. We genuinely felt a bit like the FIEGE rubbish bin, the company where you can do as you please.”

“From the moment we started using Peripass, those operators have been obliged to make an appointment and have had to work on the attitude of their drivers and back office. They have to be much better organised now. During the ‘go-live’ it was very striking that most of the drivers didn’t know their slot number. The back office had said: ‘Just drive to FIEGE’, without passing on this information to them. Now we have been live for a few months, the cases of someone still not having this reference are very few and far between.”

“We found ourselves with 17 different flows.”

“Waiting times have been shortened appreciably and that is good news for our clients. Nevertheless there are still the odd cases of a supplier complaining bitterly to our clients about ‘the long waiting times’, although fortunately thanks to Peripass we are now armed with the ideal ammunition. We are now able to see in perfect detail when the haulier arrived, when the haulage was planned for, and when it was handled. It is not our mistake if and when someone arrives far too early or far too late. For example we recently had a situation in which a supplier complained that his driver had been waiting “heaven knows how long”. In Peripass we could see that the driver had arrived at 10 a.m. and had received his access code for the barrier at 10.15 a.m. But he only actually drove in at 11 a.m. because in the meantime he had had a snooze (laughs). In that sense it would be handy if we could also allow our end clients access to those data via a dashboard.”

“Thanks to Peripass we are now armed with the ideal ammunition in the event of complaints about waiting times.”

“Our first roll-out went completely haywire. It only took a quarter of an hour for us to see that our initial set-up was completely wrong. We then deliberately let everything wallow in the mire so that we could pinpoint what the major and minor problems were, on the basis of which we drew up a strategy. One of the things that emerged at that point was that drivers didn’t know where the exit barrier was because it was poorly lit. Instead of placing an arc there, for which you would also have to arrange for a post and extra cable work, we opted for illuminating the barrier with LED strips – green on one side and red on the other, so that the direction of traffic flow was immediately clear.”

“Our first roll-out went completely haywire. It only took a quarter of an hour for us to see that our initial set-up was completely wrong.”

“We have now opted to have one large holding area outside the perimeter. As soon as the trucks have arrived and their slot becomes free, they are sent a text message with an access code. Once they are on the site they receive a message indicating the loading dock.”

“For Makro we have a separate flow because this has to be monitored more closely. Here the drivers first have to go to one of the five waiting places at reception. Depending on the reserved slot, the driver is asked to proceed to reception where the documents are checked, any changes are made, and the goods received note is prepared. As soon as that driver has moved off to one of our 50 docks, the next one is allowed into the reception area.”

So where did things go so wrong in the roll-out? “Gee, it’s a case of ‘failure to plan is planning to fail’. At least part of it is certainly down to inadequate project planning on our part. We organised the ‘go-live’ at a time when the site itself was not completely ready because the signposting was not yet in place. This led to confusion. Paper can also bend to your will. Our ideas were very convincing on paper, but in practice they proved not to be workable. So, we reviewed the internal traffic plan for the parking lot, and the lesson we drew from this was that the first ‘go-live’ should actually have been a test-run. We should also have ensured better communication with clients and suppliers. We only let them know at a very late stage that Peripass would be going live and that they had to gear their own organisation to it.”

“There was no passing of the buck, but simply an attitude of: let’s get this sorted out”

How could Peripass become even better? “An even more far-reaching reporting and dashboarding would constitute an enormous added value for me. But I’ve already pointed that out and I know they’re already working on it. This enables us to report to our own clients in a much more customer-friendly manner and to ensure that our agreed targets can be quickly and easily understood.”

What has changed since Peripass was installed? “The main difference is that we can now work much more objectively. We also have many more possibilities now for enforcing a planning and obliging drivers to keep to the slot agreements. Drivers also find this to be a fairer system. Now if they arrive too early, we check to see if we can fit them in, but if that’s not possible, they accept that. And if it turns out that we can handle them earlier, they’re grateful.”

“We can now work much more objectively, with a data-driven approach and on the basis of KPIs. That is in keeping with our international objectives.”

“In the contacts with our clients we now have more tools to fall back on when debates and arguments arise. We can now very quickly nip pointless arguments in the bud because we now have objective data demonstrating what has actually happened. FIEGE is also working much more in a data-driven manner and on the basis of KPIs, and Peripass affords us the possibility of analysing data very objectively in this respect, too: less gut feeling, more facts.”

“Our employees in goods reception are subject to much less stress now that they can at last keep the flow of drivers under control. Our staff also find it easy to work with Peripass, since it is a highly intuitive drag-and-drop platform. Communication with the drivers has also become much easier. If we don’t find a driver, we now have his contact details and can quickly contact him by calling him or sending a text message. Moreover, it’s much safer now to drive and walk around on our site, which is also reassuring. So, in a nutshell: one satisfied customer!”